I've been hitting the sketchbooks hard the last few weeks. My heart is ready for a new creative leap forward. Never thought I'd be considering apprenticing with a master blacksmith – but in order to make the pocket tools and knives I've started imagining, I want to understand the metal in a way that will only come from many hours of forging, heat and patience.

Here's to admitting I don't know a whole lot about knife-making or blacksmithing yet, but the passion to create is undeniable. Here's to casting fears aside. Here's to showing up to learn something new and putting your whole heart into it.

Here's to making my first knife.

It all begins with a steel blank.

Shaping the knife profile.

Finished profile, ready for heat treat.

Prepping the metal for a molten salt bath before going into the heat treat oven.

My knife took a nap while it bathed in the molten spa for a few minutes.

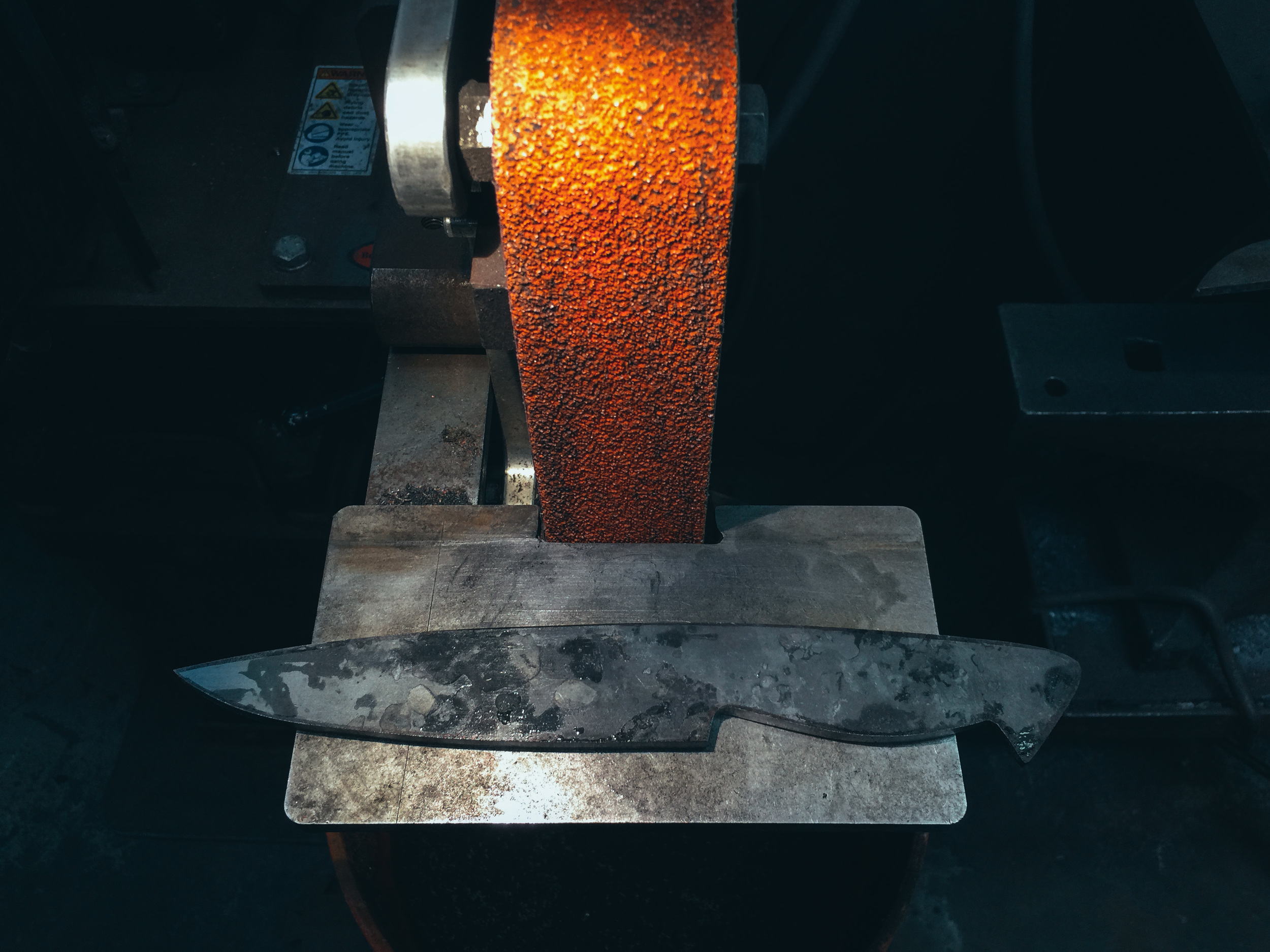

Heat treated and ready to begin grinding.

Applying the initial 45 degree cutting angle.

Let the grinding begin!

David Lisch showing us how a master does it.

First attempt at grinding a test blank. Once I finished one end, I flipped it around and went at it a second time.

First grinding the basic area of where the final cutting edge will be.

The end result and my very first knife ever.